The Hedberg

Fletcher Insulation Place Artists Centre Stage

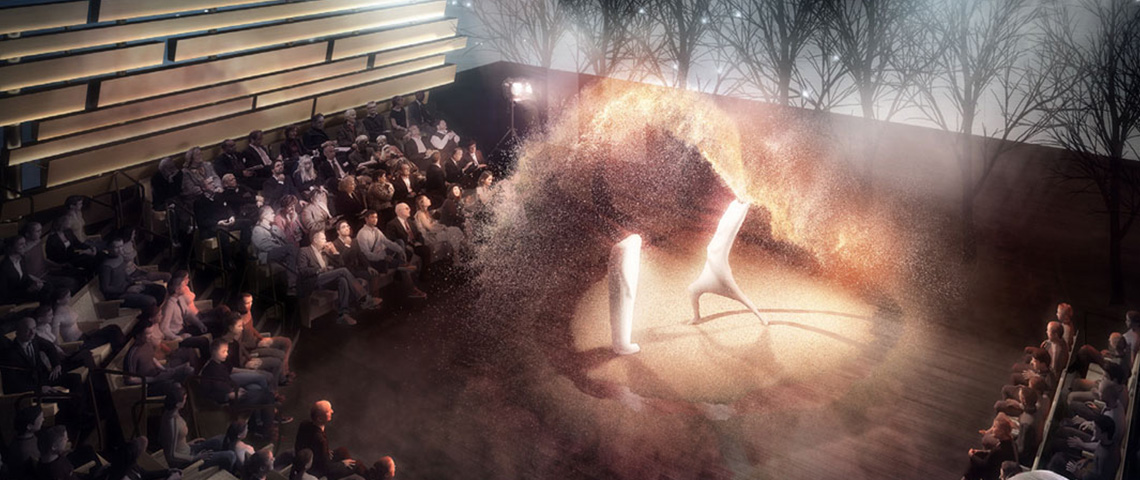

When completed, the Hedberg will be a landmark contemporary performing arts and creative industries precinct in the heart of Hobart’s historic Theatre Royal district. In partnership with the University of Tasmania and the Tasmanian Government, the $96 million project represents a major refurbishment and new build creating a world class performance, research and teaching facility in the Hobart CBD.

In the music and performing arts space, ensuring that the artists take centre stage, not the HVAC systems, was true science. Fletcher Insulation offered a product range that provided a superior acoustic and thermal insulation performance solution to the Hedberg, to ensure audiences will feel and hear the performance, and not the air conditioning.

The Hedberg

The Hedberg is a new creative industry and performing arts project, incorporating Hobart’s Theatre Royal and the University of Tasmania’s Conservatorium of Music. The project includes a contemporary building integrated with one of Hobart’s historic landmarks, the Theatre Royal. Delivering an energy efficient solution within the rigorous acoustic, thermal and energy performance specifications required a different way of thinking and Fletcher Insulation’s product range was the ideal solution for such a challenging requirement.

The Contractor’s Challenge

Degree C is one of Tasmania’s leading contractors with more than 25 years’ experience delivering quality HVAC solutions for a wide range of projects. As the mechanical contractor on the project, Degree C faced a number of technical challenges with acoustic performance and thermal efficiency rated as the first and second most important aspects in the HVAC design.

Performing arts spaces are complex environments to heat and cool for a number of reasons. The spaces are often utilised at less than full capacity for rehearsal and preparation, whilst capacity (and hence loads) increase enormously during performances under lights with a full audience. During all these circumstances the equipment must operate across a wide load profile, all the while maintaining whisper quiet operation. In the recital hall for example, the air handling units designed to supply comfortable conditions for the audience, were required to undergo rigorous factory testing by an independent acoustic consultant to ensure that the units could maintain the tight operating parameters required. The air handling units were prefabricated with Fletcher Insulation FI32 Semi Rigid insulation faced with Vapastop® 883 and passed all quality and acceptance testing prior to delivery on site. Fletcher Insulation worked closely with the Degree C team to ensure the product range selected and delivered met the required design performance specifications.

Designed as one of Tasmania’s first integrated BIM projects, the Hedberg Building meets Green Star design requirements, and the stringent documentation this entails. During design, every element needs to be considered for the BIM model, prior to fabrication including the insulation on the HVAC equipment and ductwork. Fletcher Insulation’s extensive product documentation including detailed performance data, supported by independent Fletcher Insulation Product Location Application FI32 Semi Rigid 25mm and 100mm faced with Vapastop® 883 Air Handling Plant Acoustic Control, Thermal Performance, Condensation Prevention FI32 Semi Rigid 25mm and 50mm faced with Vapastop® 883 HVAC Ductwork Acoustic Control, Thermal Performance, Condensation Prevention.

“Richard and his team at Fletcher Insulation have always been very helpful when selecting the right product for an application. Whether it is duct lining, PIR panel, or insulation duct wrap, Fletcher Insulation have the product and the expert advice for any insulation application”.

Mr Chris Fontana, Divisional Manager Degree C.

and in-house test data, and personalised technical support, enabled Degree C to deliver on the GreenStar documentation requirements.

Given their longstanding relationship with Degree C, Fletcher Insulation’s range of acoustic and thermal insulation products made sense. As Chris Fontana, Divisional Manager with Degree C stated “the quality of Fletcher Insulation’s documentation made the approval process easy when submitting to the consulting engineers for the project.”

The Fletcher Insulation Product Solution

The key to Fletcher Insulation’s approach is ensuring the right solution for our client’s projects, whether it’s thermal performance, acoustic control, condensation prevention, indoor environment performance, or fire resistance. For the Hedberg project, Fletcher Insulation’s local team worked in closely with Degree C’s designers to understand the specific project performance requirements and selected the best products to meet these requirements

Testimonial “Richard and his team at Fletcher Insulation have always been very helpful when selecting the right product for an application. Whether it is duct lining, PIR panel, or insulation duct wrap, Fletcher Insulation have the product and the expert advice for any insulation application”. Mr Chris Fontana, Divisional Manager Degree C.

Product Specification

The FI32 Semi Rigid Glasswool Insulation range is the ideal choice as an internal liner for fabricated air conditioning ductwork where acoustic, water vapour and air quality management are required.

The use of Vapastop® 883 Facing Foil adhered to FI32 Semi Rigid Glasswool Insulation is ideally suited to applications where high tear strength and puncture resistance are required in addition to a high degree of flexibility without delamination of the aluminium foil.

The aluminium foil facing has a very low permeance to water vapour and other gases, which makes Vapastop® 883 ideal for air handling ductwork. The strong and durable vapour barrier helps prevent fibre erosion of the glasswool insulation lining, which otherwise can lead to fibres entering the air-stream of the HVAC system.

Vapastop® facing provides excellent acoustic absorption without the need for perforation when applied to glass wool insulation blanket and boards. The sealed, nonperforated surface of Vapastop® 883 provides a superior alternative to the combined facing option of HDP (heavy duty perforated foil) and Mylar/ Melinax film, while still offering exceptional sound absorption performance.

Heating, Ventilation, Air Conditioning (HVAC) Insulation Solutions

Fletcher Insulation has been at the forefront of insulation technology since the 1930’s. With a national distribution footprint, we pride ourselves on providing excellent service to our customers.

Whether you are designing or selecting materials for a residential, commercial or industrial project, you can trust Fletcher Insulation to deliver the best insulation solution for your HVAC applications.

Built in Australia, the Fletcher Insulation range has been tested to Australian Standards and Australian conditions. Designed to meet the strict requirements of the latest National Construction Code (NCC), our products meet and exceed the NCC’s deemed-to-satisfy requirements anywhere in Australia. Our specialist range of fire rated, thermal, acoustic, condensation control and indoor air quality solutions ensure your project is covered, with the full backing of our experienced sales and support team.

Sustainability is at the heart of what we do. Our strong focus on well-being, comfort and improving quality of life inspires us to design, manufacture and deliver world class insulation solutions for the built environment.

Insulation plays an integral role in the design of high-performance buildings. Factors such as the climatic conditions, building design and usage can have a significant impact on the comfort and well-being of occupants.

Fletcher Insulation has an extensive range of HVAC and industrial insulation products to suit your project and application. Speak to a representative today to see how our clients and Fletcher Insulation are building better, together.

Speak to a representative today to see how our clients and Fletcher Insulation are building better, together.

Enquire Now

Download Now